At Shuowei, we’re dedicated to delivering advanced wood-drying solutions for various industries, from wood panel manufacturers to furniture makers. Recently, we collaborated with a woodworking school in Rwanda, where we installed our easy-to-use high-frequency vacuum kiln. This project showcased our technology’s effectiveness in African hardwood drying, proving it’s not just powerful but also operator-friendly, making it ideal for both professionals and beginners.

Overcoming the Challenges of Drying African Hardwood with a High-Frequency Vacuum Kiln

In this project, our task was to dry 100mm thick African hardwood—a dense and notoriously difficult material to work with. Typically, conventional kiln drying wood of this thickness can take months, and if not done carefully, it often leads to cracks, warping, and uneven results.

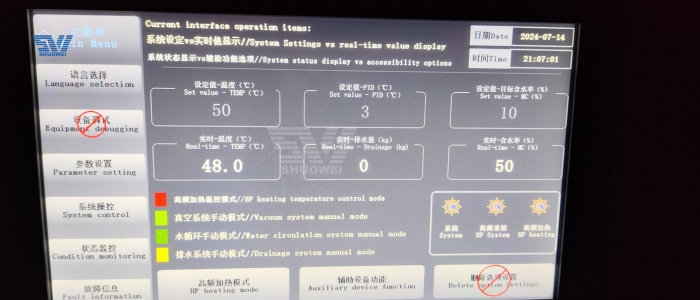

However, with our touch-screen high-frequency (HF) vacuum kiln, we successfully overcame these challenges. The kiln is not only powerful but also designed to be easy for operators of all skill levels to manage while still delivering top-notch results.

Efficiently Drying Thick African Hardwood with Precision Control

African hardwood is known for its toughness and high moisture content, which can make drying a complex process. Our clients, including wood flooring companies and sawmills, often face these challenges when working with such dense materials. Conventional drying methods can be slow and prone to errors if not closely monitored.

In this case, the school needed a kiln that could handle wood with a moisture content as high as 99% and bring it down to a stable 6-8% in just 8 days. Thanks to our HF vacuum kiln’s precise control over temperature and pressure, the drying process was efficient and consistent. Even better, the kiln’s intuitive touch-screen controls made it easy for the school’s staff and students to operate confidently.

Reliable Results with Simple, Smart Technology

The outcome was impressive: the hardwood dried evenly without any of the usual issues like cracking or warping. This result proves just how versatile our kilns are. Whether you’re running a large-scale operation or a smaller workshop, our technology makes the wood-drying process both simple and reliable.

For our clients—including wood processing factories, furniture manufacturers, and wood carving workshops. This project highlights how our equipment seamlessly integrates into a variety of settings. We design our kilns with the operator in mind, ensuring that they’re straightforward to use while consistently producing excellent results.

Hands-On Training to Ensure Success

This project was a success not only because of our technology but also thanks to the dedicated work of our engineer, Mr. Li. He oversaw the installation and provided hands-on training to the school’s staff, ensuring they could confidently operate the kiln long after the initial setup. His commitment to supporting the school’s team made all the difference in ensuring smooth, successful operations.

Why Choose Shuowei for Your Wood-Drying Needs?

With over 34 years of experience in wood drying, Shuowei Machinery has earned its reputation as a leader in the field. From large furniture makers to smaller, specialized workshops, we’re committed to providing reliable, easy-to-use equipment that meets the highest industry standards. We’re proud to deliver drying solutions that help our clients achieve their goals, no matter their scale.

Let’s Simplify Your Wood-Drying Process

If you’re searching for a wood-drying solution that’s both effective and easy to use, look no further. Our kilns are designed to make the drying process as smooth as possible, regardless of the size of your operation. Contact us today for a free consultation, and let’s explore how our technology can support your business.