When it comes to woodworking, properly dried lumber is the key to success. The debate between kiln drying vs. air drying wood often arises, as each method impacts stability, durability, and resistance to insects and decay. Freshly cut wood, loaded with moisture, must be dried to make it suitable for building or crafting furniture.

But what’s the best method for drying wood—kiln drying or air drying? Let’s break it down and guide you to a smart decision!

Why Moisture Content Matters

Freshly cut wood, also known as green wood, has a moisture content (MC) ranging from 30% to 45%. For woodworking projects, achieving an ideal MC of 6%–9% is crucial.

Why?

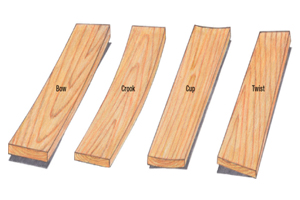

- High MC leads to warping, cracking, and adhesive failure.

- Wood naturally absorbs and releases moisture with environmental changes, causing expansion and contraction.

Using a reliable moisture meter is essential to measure MC and ensure your lumber is project-ready.

Ideal MC for Projects

Different projects require specific MC ranges:

- Indoor projects: 6%–8%

- Outdoor projects: 9%–14%

- Hardwood flooring: 6%–9%

The goal is to match the wood’s MC to your location’s equilibrium moisture content (EMC).

How to Measure MC

Accurate MC measurement is non-negotiable. Here’s how:

- Moisture meter types: Pin and pinless.

- Recommendation: High-quality pinless meters are best for non-invasive readings.

- Pro tip: Invest in a trusted brand with technical support for reliable results.

Air Drying Wood

Air drying removes “free water” from wood cells through natural airflow.

Process:

- Stack wood with stickers to allow airflow and even weight distribution.

- Cover the top with waterproof material to prevent rain damage.

- Dry outdoor to ~15% MC, then move indoors for final drying.

Environmental Requirements:

- Requires open, dry spaces, avoiding damp ground and surrounding plants.

- Ideal conditions to prevent fungal growth, especially for wood prone to mold, such as pine.

Pros:

- Stability: The slow drying process allows the wood to contract gradually, making it more stable and reducing the likelihood of warping or cracking. This makes it easier to work with hand tools and ensures the wood maintains its natural shape, ideal for fine woodworking.

- Appearance: Maintains natural color and grain richness, especially in woods like cherry or walnut, giving it a more visually appealing look.

- Suitability for Hand Tools: Wood dried slowly is more stable and easier to work with, especially for hand tools, as it tends to remain intact during processing.

Cons:

- Slow Drying Process: Drying can take up to a year for every inch of thickness.

- Insect Infestation Risk: Higher risk of insect infestation if improperly stored.

- Potential Risks for Furniture Making: While the wood dries slowly and naturally, achieving the right moisture content for furniture making can be tricky. Air-dried wood may still face risks like dimensional instability when subjected to seasonal humidity changes, resulting in furniture that may warp or shrink over time, requiring costly repairs or replacements.

Kiln Drying Wood

Kiln drying applies precise heat and air circulation to dry wood quickly and effectively.

Process:

- High temperatures (~170°F) remove “bound water” from wood cells.

- Effective in killing insects and mold.

Pros:

- Speed: Kiln drying is much faster than air drying, taking only 6-8 weeks compared to the 8-16 months required for air drying.

- Pest Control: High temperatures effectively kill insects and mold, providing an added benefit of pest-free wood.

- Immediate Usability: Once the wood is dried, it is ready for use immediately, including for painting or construction, which is ideal for industrial projects.

Cons:

- Potential for Internal Tension and Brittleness: Due to the rapid drying process, kiln-dried wood can sometimes develop internal stresses, which may cause it to become brittle, leading to cracking or deformation if not carefully managed.

- Appearance: Kiln-dried wood tends to lack the natural richness and color depth of air-dried wood. The rapid drying process tends to make the wood appear more uniform and less visually appealing, which might not be ideal for high-end furniture or artistic projects.

- Drying Quality: If not carefully monitored, kiln drying may result in uneven moisture distribution, causing defects like cracking or warping if not done correctly.

Additional Technical Considerations:

- Careful Control of Drying Process: To avoid issues like surface cracking or “shell hardening,” the drying cycle must be carefully managed to prevent excessive speed and temperature fluctuation. This can help prevent internal damage, such as the formation of honeycomb patterns in the wood.

Real-Life Case Study: Mixing Air Drying and Kiln Drying

Let me share a story about my client, Gene, who runs Hobson Hardwood in Missouri.

Gene initially air-dried his domestic and exotic hardwoods for 12 months, reducing the MC to 15%. Then, he used a high-frequency vacuum kiln to finish the process, bringing the MC down to 8% in just 10 days.

Results?

- Faster production without sacrificing wood stability.

- High-quality furniture-grade lumber ready for immediate use.

Gene’s hybrid method combines the best of both worlds: the natural beauty of air-dried wood and the efficiency of kiln drying.

Kiln Drying VS Air Drying Wood: Choosing the Right Method

Here’s a clear breakdown to help you decide:

| Feature | Air Drying | Kiln Drying |

|---|---|---|

| Speed | 8–16 months | 6–8 weeks |

| Cost | Low | High |

| Stability | High, with slow drying | Moderate, due to internal stress |

| Appearance | Rich color, natural finish | Lacks natural richness |

| Insect Control | Low, unless treated | High, due to heat |

| Processing Performance | Better for hand tools, easier to cut and shave | Suitable for machine processing, but more prone to cracking or splintering |

Pro Tips for Wood Drying Success

- Match the drying method to your project’s timeline, budget, and quality needs.

- Use a high-quality pinless moisture meter like Wagner to ensure precision.

- For large-scale projects, consider a hybrid approach: air-dry to ~15% MC, then kiln-dry to 6%–9%.

Conclusion

Whether you choose air drying for its stability and natural beauty or kiln drying for speed and efficiency, both methods have their merits. For most indoor furniture projects, kiln-dried wood is the go-to choice. For outdoor projects or artisan pieces, air drying is hard to beat.

Got questions about drying wood or your next project? Reach out—I’d love to help!