With the development of technology, now more and more people are very familiar with vacuum drying system, Its principle is simple and easy to control, mainly consists of a well sealed chamber and a vacuum pumping system but the final performance and dying results are much better than traditional ways, lower water boiling temperature and shorter drying circle, let alone that it well solved the wood defects caused by high temperature.

Of course there is also many limits for vacuum wood drying, below are some points that usually listed by some opponents.Let’s talk one by one, then you will finally find something pretty interesting

The Chamber Is Usually Small And The Drying Business Scale Is Limited, Even So, There Will Be Stickers And Heating Plates That Occupied Nearly Half Of The Valuable Room.

For the vacuum chamber, it is really important and it directly related to the output of the kiln, a good vacuum chamber should be well sealed, and because there is atmospheric pressure difference, it should be very stable and strong. Now there are mainly two kinds of chamber, one is round and the other is square, Round shape is good to stand the pressure, but it is also easy to see, for the square slabs, the loading percentage will be much less than square one, To meet the standard, now the square chamber is usually made of stainless steel, while for round ones they use carbon steel to lower the cost.

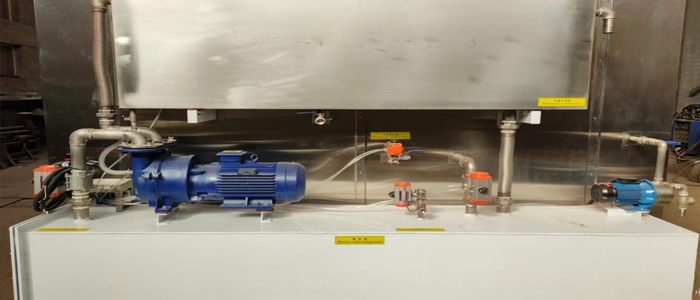

Then it is about the room in the chamber, the things listed in No 1 do exist, but nowadays the combination of high frequency and vacuum drying well solved this problem, the principle of high frequency or radio frequency is using the wood as a capacitor, and the water will then heat itself, it is similar like the Microwave Oven in your kitchen, but this kind wave is with better penetration capacity. Heating the wood core and surface at the same time could also avoid the cracking due to uneven water contents which is commonly seen in the traditional heating ways. This kind of heating allow the operator to stack the wood without spaces, then make the best use of the chamber room. Below is a Pic of the Shuowei vacuum wood drying kiln, it is a well sample of the combination of these two technologies, if you are interested just feel free to leave a message.

In my next passage i will show you more about the vacuum drying kilns, let’s meet again later.