High-Performance Lumber Drying Kiln

Our lumber drying kiln models are the most recommended agile solutions you can find than any wood drying kiln manufacturer.

This high-performance kiln lumber drying suits your usage needs, with:

- Automatic wood drying kiln feeder system and components for easy operations and lumber dry kiln controls

- Choices of custom-sized best dehumidifier for wood kiln drying. It even fits as a small wood kiln dryer for woodcrafters.

- High frequency dryer equipment providing crack-free, and no discoloration kiln-dried wood for furniture manufacturers.

- High-capacity vacuum kiln dryer that works best for sawmills, large plants, and other lumber-drying kiln business scales.

High-Performance Lumber Drying Kiln

Each of our kiln-dried timber models is at par with other types of wood-drying kilns for sale in stores near you. Simply, for the reason of providing sustainable and expert-recommended wood drying business solutions. We ensure as a wood-drying kiln manufacturer that our products are not only operations-friendly but are reliable partners of your business nowadays.

You can compare it to any kiln dryer for sale in the market in terms of the cost of kiln drying lumber . All our timber kiln dryers equipped with custom wood drying kiln technology pass through a systematic development process . Our team of wood kiln experts makes it possible to address every kiln drying specification of our customer for the best wood drying quality results. Being the most sought lumber dry kiln manufacturer, we have custom kiln drying designs to help your high-performing business thrives.

We provide an array of high-capacity lumber kiln generation dryer equipped products for fast lumber kiln drying schedules and easy-to-control components.

Product Category

Large Lumber Drying Kiln

Accommodates high-volume wood drying that allows ample airflow, temperature, and humidity control for rapid drying while maximizing space. Completes all types of high capacity lumber drying that leads to an efficient flow of revenue.

High-Frequency Vacuum Kiln 12.0

High-capacity hydraulic pressure kiln timber drying system. It helps you understand how to build a lumber drying kiln that leads to efficient wood storage and loading and cash flow.

High-Frequency Dehumidification Vacuum Kiln 10.0

Caters to a medium capacity kiln drying volume of about 10 cubic meters that dehumidifies and dries lumber fast. Best for average-sized plants and sawmills.

High-Frequency Vacuum Kiln 8.0

Medium-sized vacuum kiln for faster and consistent drying without cracking or warping damages. Effective and easy to operate while reducing the cost of labor.

High-Frequency Vacuum Kiln 6.0

One of the most upgraded kiln systems with state-of-the-art technology used globally. Prevents discoloration and defects while quickly drying the wood.

High-Frequency Vacuum Kiln 4.0

Mostly used in the wood industry for its small dryer capacity that is easy to handle and mobilized. Its 4.4 cubic meters kiln capacity best deal with dried lumber for small wood mills, carpenters, and furniture crafters.

Product advantages

Training & Technical Support

We ensure that making a kiln to dry wood comes with continuous training and technical support.

Easy To Control Operations

Features a superior management system for lumber dry kiln controls. Even those already used wood kiln for sale in the market are loved for their being easy to operate.

Fast & Automated Structure

Extensively easy and flexible structure for great maneuverability and ample space heaters. Provides quick drying and an automated mechanism.

Fully-Customizable Capacity

Our lumber kiln dryers have full-customization options among lumber drying kiln for sale in the market. They can cope with any wood kiln drying time chart.

Quick drying process

The cost of kiln-drying lumber is considerably low because of its quick and efficient drying process. It is more or less five times faster than ordinary drying kiln systems. The heating process does not quickly dry the wood but causes a self-heating effect. Making the kiln drying process from the inside out leaves no moisture content.

Electric Lumber Drying Kiln

Our kiln dryers are safe for the environment with the use of electric power than other kilns that use boiler systems. The use of an electric-powered kiln drying after over decades of research and development makes the wood durable and free of cracks and warping.

Quality of Customer Service

Your satisfaction is guaranteed with the quality of our services from consistency, and reliability, to flexibility and cost-effectiveness of the lumber drying kiln systems. We see to it that we do not only meet your kiln drying product specifications but step up to your growing business needs. Our quality customer services are in agreement with your expectations, and the ACE (Accurate, Complete, and Excellence) index of our existence. Your changing demands and crises are our priority for a mutual accord that values the most worth for your money .

Company Advantage

Our fully customizable lumber drying kiln products have been polished by 32 years of research, innovation, and development. Each of our customers from around the world has optimized their lumber drying kiln business. Thanks to the durability, low maintenance, and toughness features of our kiln systems. The custom high-frequency vacuum kiln, anti-rust by stainless steel surface, and all the high-performance lumber drying kiln products are at the forefront of their growth.

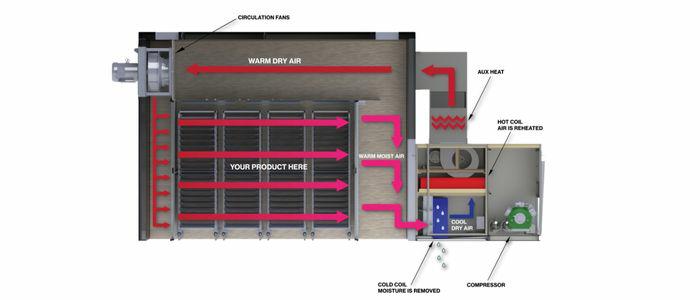

How Our Kiln Product works

Make careful selections of how you will use your kiln and how long to kiln dry wood, check these kiln factors. The size of your kiln, the power to use, and the capacity you desired is vital. We make sure that our dry-kiln dryers are up to every usage scenario you have. Make it work to your choosing and you will no longer resort to a wood-fired lumber kiln even if it’s for a DIY lumber drying kiln purpose.

Lumber Drying Kiln Effect

All our dry-kiln drying devices are electric-powered and have self-protect features that are widely used for sawmills, furniture making, plant floor installations, and wood carpentry. Our reputation as a leading vacuum lumber drying kiln manufacturer in China continuously builds trust among customers.

Product Showcase

Kiln Dryer Machine Adaptability To Raw Material Specifications

The basics of the lumber drying kiln process start from the raw material specification list. Such fundamental listing includes the frequently used kiln drying methods, kiln size or capacity, safe handling & control, and quality of dried lumber products. Take note of your needed wood drying schedules, as well as the precautions and defects, and the type of raw material to load. Your kiln dryer machine should adapt to these raw material specifications for a complete drying process.

Effective Moisture Content (MC) Solution

The amount of moisture in the dried lumber under normal conditions is about 6 to 8 percent when using lumber kiln drying. The reduction of moisture content relies on the space heating environment. Which is significantly more favorable with the use of our new generation kiln dryers than the natural or air-drying method.

Protective HF Features To Handle Various Wood Species

There are factors and incurring damages or defects when it comes to wood drying of various wood species. So it is important to select your Lumber Drying Kiln Manufacturer that specializes in the use of high-frequency (HF) wood drying technology. Most importantly, the use of an HF vacuum kiln model prevents defects such as shrinkage, swelling, warping, and cracks, fast and reliable over time.

Heating environment Requirements for Kiln Drying

The amount of moisture in the dried lumber under normal conditions is reduced by about 6 to 8 percent when using lumber kiln drying. This heating condition happens and relies on the pressurized airflow in a vacuum kiln space heating environment. In this scenario, the heat transfer to the wood and moisture reduction is faster in these new generation kiln dryers than in the natural or air-drying method.

High-Quality Kiln-dried Wood Products

Our high-frequency vacuum kiln dryers are customized to produce high-quality kiln-dried wood for small and large volume capacities. The quality of each kiln-dried wood is mainly the result of specially-designed new generation HF-equipped dryers. Customers from Canada, America, and Asia love each kiln model they got from us for use in their furniture factories, wide slab woodcraft, and tabletop production.

Safe and Environment-Friendly Lumber Dry Kiln Dryers

Aside from the product quality aspect like strong kiln-dried wood that is free from defects and damages, safety and environmental aspects are our top priority. Every lumber dry kiln dryer we develop and release for various users or customers is certified to national and international quality, environment, and safety standards.

Fast Lumber Drying Time

The use of wood drying kilns in the advent of high-frequency vacuum dryers makes the trend a fast and most reliable lumber drying technology. The atmospheric temperature and airflow inside these new generation kilns produce vacuum pressure to dehumidify and drain out excess moisture for quick wood dehydration from the inside out.

high-performance Lumber drying Kiln

Shuowei is a Wood Klin Manufacturer in China that produces custom-sized vacuum lumber drying kiln products. Shuowei’s kiln variants include the most advanced, high-frequency drying technology and high-performance wood solutions to suit your lumber dry kiln business.

our service

- Highly adaptable vacuum kiln dehydration technology , easy operations and control system automation

- Our Kiln drying systems are built with more stable and non-collapsible structure

- The square shape facilitates easy wood loading and maneuverability for controlled heating

- 32 years of product research, innovations and advancement involve rigorous process and product continuous improvement

- Highly experienced product development from standard wood drying, custom vacuum kiln, enhanced dehumidification kiln drying schedules, to hydraulic pressure system kiln

- Proven toughness and durability upgrades on interior insulation and anti-rust surface with stainless steel exterior

- Rapid evolution towards high-capacity vacuum kiln with high-frequency generator as the core technology.

- Efficient electric-powered dehumidification with a high-speed direct heating method for a uniformed and inside-out dehydration effect .

- Custom lumber drying kiln system training aside from easy to understand user specification and instructional manuals

- The best technical product support to all our customers for longer product lifetime.

Have more questions please contact us

lumber drying kiln faq

You can quickly drain and dry moisture content from the wood with the use of a Kiln. The kiln drying process keeps the consistency of the wood’s size and quality to make easy installations of the kiln-dried woods . Kiln-dried lumbers are seen to have been loved by most customers as they are free from shrinkage, crack, and warping damages.

Easily understand your wood drying needs like power type, technology to use, and other factors to get a suitable kiln for your needs. Ensure to include in your selection the species of woods, whether it’s hardwood, slab thickness, moisture levels, and drying time. This will help you know the exact fit of your needed kiln for practical utilization.

The drying process of a high-performance vacuum kiln drying uses a high-frequency wood dryer kiln system. It can benefit you with an average drying cycle time of about 6 days or shorter to completely dry a quality kiln-dried wood. Of course, it is faster to dry thin, air-dried slabs, and softwood-type lumber than the freshly cut, thick-slab and hardwoods.

The kiln drying chamber shortens the duration of the drying as compared to air drying and conventional kiln. It dries up inside-out the wood by extracting the air out in vacuum mode with the help of a vacuum pump. When properly done, the vacuum kiln -dried woods are free from defects and kills pest infestations.

Drying lumber using a kiln involves a vacuum chamber or an air furnace that controls the airflow, temperature, and humidity factors. The moisture content of the lumber is controlled and reduced to an acceptable level, at a much shorter time and defects-free.

You need to do an easy cleaning after each lumber drying schedule for a day’s maintenance works of the vacuum kiln chamber. Each chamber is made of stainless steel protection to prevent oxidation and rust formation. Nothing to worry about the high-frequency generator as it is equipped with top-brand electronic system control and self-protect programs.

The vacuum dry kiln is the most energy-efficient kind of wood drying type. It uses a precise pressurized air furnace for more controlled air circulation and wood dehydration. It can even accommodate high-capacity wood drying loads at the fastest rate of dehumidification.

Yes, the vacuum dry kiln model is designed for precision control. It means, fewer touch and end-check controls after its installation. The vacuum kiln can accurately control and set the drying factors as to heat, moisture target, humidity level, and pressure points, among others. Much more than that, these high-performance kiln models prevent wastage and maximize production volumes.

We can tailor-fit each vacuum lumber dry kiln model for the specific need you will require for various scenarios and user specifications. Our technical team can offer you a wide selection of custom wood drying vacuum kiln products enjoyed already by our customers.

Choose those with a product development track record, research and development advancements in wood drying technology, and years of customer-centric quality upgrades. These are a few benefits that lead to a cost-effective lumber drying process to boost your cash flow. Indeed, enjoyed by customers across the world as from our being a reliable wood kiln manufacturer.

We'd like to work with you

If you have any questions or request a quote, please send us a message. Our experts will reply you within 24 hours and help you choose your suitable wood drying kiln, and can also help you solve wood drying problems.