High-Frequency Vacuum Wood Machine adopts high-frequency drying, inside and outside of wood timber is heated at the same time, uniform heating, high-speed drying, short time and good quality, which may keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking especially applied for the thick and hard precious wood, wet wood.

High frequency is also called radiofrequency, it is a kind of direct heating. The principle is using the wood as a medium, capacitor is a group between two pieces of the metal plate.Then give them voltage, the electric field produced between the two plates. The water molecules between electrodes will be polarized by the alternating magnetic field and move in very high speed rapidly.

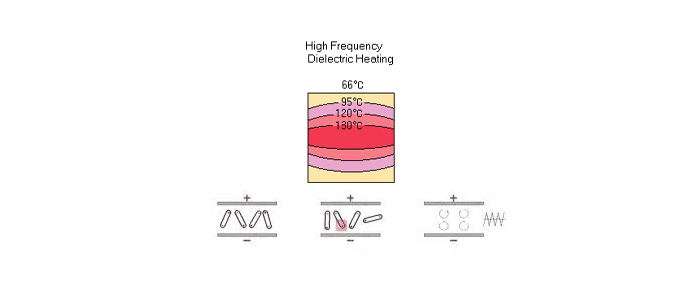

The impact and friction (billions of times per second) among water molecules creates heating in a very short time. The conventional steam kilns or common vacuum kilns use the heating transfer to dry the wood from the surface to core. high frequency power does not heat wood moisture but make wood moisture heated themselves. It is a kind of directly heating, This continuous effect let whole wood heated surface to the core wholly and uniformly. That is one of the reasons why the high frequency vacuum machine is 10 times faster than a conventional wood drying kiln.

The hardwood from 30% moisture content to 8-10%MC only take 4-6 days and the fresh cut wood only take 10-12 days to get 8-10% moisture content.

Our kiln also adopts vacuum dehydration technology. The stainless steel vacuum pump can make the vacuum oven reach -0.093Mpa condition. The vacuum condition is to make water vaporized in low temperature below 55 ℃. At the same time, vacuum can also suck the wood moisture out. The machine cooling system will separate the hot air and hot water out, then cool them and release them out. Wood is drying under a vacuum and wet condition at low temperature. That will ensure wood is no cracks and keep the wood nature color.

The Biggest Advantage

1. Penetration heating on the plate is the biggest advantage of High frequency dry,to dry wood inside and outside at the same time.

This high-frequency characteristics will be doomed its mahogany and hardwood lumber drying class has unique advantages.

2. The drying speed several times or ten times that of conventional steam kiln.

3. And because of the precise wood temperature control,it can make the wood not cracking,there would be no buckling deformation,greatly improve the timber material yield,especially for larger than 5 cm thick wood.In total,high-frequency vacuum drying method is the best solution.

If you are interested in our high frequency vacuum dry kiln, send inquiry or contact us for more details.