A kiln is a crucible in which a substance is subjected to carefully controlled elevated temperature. Making lumber involves heating it until a chemical change, such as polymerization, renders the wood more flexible and less prone to split when nailed or screwed.

This is because wood fibers comprise long chains of cellulose, which can be broken down as the temperature rises. Making a kiln is a good idea if you’re in the business of lumber. By making your own, you can cut down significantly on costs. Some people like to turn their scraps into lumber and need something that they can use to dry the wood quickly.

A kiln is something you can make at home when you have the directions you need. Here’s what you should know before building yourself a lumber kiln.

How To Make A Kiln For Lumber

If you are a person who loves to work with wood, you may want to consider investing in a lumber kiln. A kiln is used to dry lumber to be more easily worked with. It can also help protect the quality and durability of the lumber itself by ensuring that it has the right amount of moisture content before use. For many hobbyists with access to scrap wood, making your own lumber kiln is a great idea. Here are some steps to help you make one:

The first step in making your own lumber kiln is to choose the right location for it.

Ideally, you should find an area that is open and has good ventilation so that moisture will be able to escape easily from the kiln. You should also try to find a place that is not prone to extreme temperature fluctuations or high levels of humidity, as too much moisture can negate the benefits of drying your lumber in the first place.

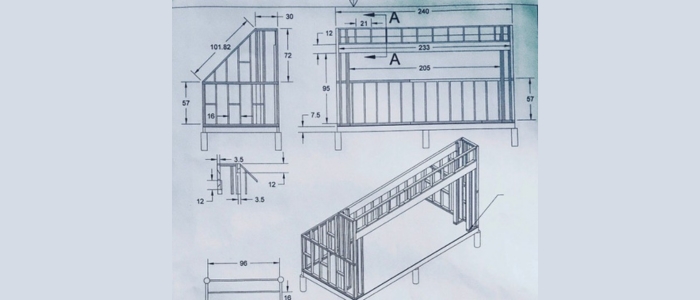

Once you have found the right location for your lumber kiln, you need to gather your materials and start building it. The materials that you will need for a lumber kiln include wood, glass or plastic sheeting, staple gun and staples, tape, saws of various kinds (including circular and jigsaw blades), screws and nails.

You should start off by creating the frame for your lumber kiln. This frame should be large enough to accommodate the size of the lumber you will be drying. It should also have a roof so that moisture won’t get into your kiln from above. For example, shipping containers are an excellent frame option that is easy to find. Once your frame is built, cover it with a plastic or glass sheeting material to help seal in any remaining moisture.

The next step is to build the shelves for your kiln, where you will lay the lumber to dry.

It is important that these shelves be evenly spaced so that the lumber can make good contact with them and they will also help promote proper airflow.

Once your kiln is built, you need to install a fan inside it. This will ensure that moisture can escape from within the kiln more easily and keep your lumber from becoming too wet.

The final step in building your own lumber kiln is to test it out and make sure that everything is working properly.

You should monitor the temperature, moisture content, airflow and overall performance of your kiln as you are drying your lumber so that you can adjust any settings as needed.

If you are interested in working with wood, a lumber kiln is an essential tool. With suitable materials and some basic carpentry skills, you can easily build your own lumber kiln at home. Remember to keep monitoring the temperature and moisture content of your lumber as it dries and make adjustments as needed for best results.

How do you make a homemade lumber kiln?

There are several steps involved in making a homemade lumber kiln:

- The first step is to choose a location for your kiln that is open and has good ventilation, so that moisture can easily escape from the kiln as the lumber dries. You will also need to gather the necessary materials, such as wood, glass or plastic sheeting, staple gun, staples, tape, saws of various kinds, screws, and nails.

- Once you have your materials ready, you will need to build the frame for your lumber kiln. This should be a large enough space that can accommodate the size of lumber you are drying, and should also include a roof to prevent moisture from getting into the kiln from above.

- Once the frame for your lumber kiln is built, you will then need to cover it with a sheet of glass or plastic, using a staple gun and staples to secure it in place.

- Next, you will need to build the shelves inside your lumber kiln that the wood will be laid on as it dries, making sure that the shelves are evenly spaced for maximum airflow.

- Once your lumber kiln is built, you will then need to install a fan inside it to help promote better airflow as the wood dries.

- Finally, you should test your lumber kiln to make sure that everything is working properly and adjust any settings as needed. With these steps, you can easily make your own homemade lumber kiln at home.

Frequently Asked Questions

What is a lumber kiln, and how is it used?

A lumber kiln is a specialized tool for working with wood that uses controlled heat, humidity, and airflow to dry lumber. This enables the wood to be cured properly and reduces the risk of warping or other damage as it dries. Lumber kilns are typically used by woodworkers and carpenters to dry lumber that they have worked with or plan to work with in the future.

Is it better to kiln-dry or air-dry wood?

There is no definitive “right” answer to this question, as both kiln drying and air drying can be used successfully for woodworking purposes. However, many experts recommend using a lumber kiln in order to ensure that the wood dries properly and does not warp or become damaged in any way. Kiln drying also has the advantage of being a faster method, which can be useful if you are working with time-sensitive projects.

Are there any safety precautions that should be followed when using a lumber kiln?

Yes, there are several key safety considerations to keep in mind when using a lumber kiln. These include ensuring adequate ventilation in the area where you are drying wood, wearing protective clothing and gear such as gloves and goggles, and following all of the manufacturer’s instructions closely. Additionally, you should always exercise caution when working with any power tools or machinery in order to prevent injury.

How can I ensure that my lumber dries properly using a lumber kiln?

There are several steps that you can take to ensure that your lumber dries properly when using a lumber kiln. These include monitoring the temperature and moisture content of the wood, as well as making adjustments to these factors as necessary based on your specific project. You may also want to consider using a hygrometer in order to keep track of the moisture level in your kiln. Additionally, you should take care to regularly inspect your entire lumber kiln for damage or other issues and make necessary repairs as needed.

How long does it usually take to dry wood in a lumber kiln?

The length of time that it takes to dry wood in a lumber kiln will depend on a number of factors, including the type and size of the wood, the temperature and humidity levels inside the kiln, and the speed at which you want to dry your wood. Generally speaking, it typically takes between 2 and 6 weeks for wood to dry in a lumber kiln fully.

However, other factors may increase or decrease that time frame depending on your particular situation. It is important to monitor the drying process closely and make any necessary adjustments as needed in order to ensure that your wood dries correctly.

How can I be sure that my lumber kiln is working properly?

There are several steps that you can take to ensure that your lumber kiln is working properly when drying wood. These include checking the temperature, humidity, and airflow inside the kiln regularly, making any necessary adjustments as needed, and inspecting the entire kiln for damage or other issues. Additionally, you may want to consider consulting with a professional lumber kiln manufacturer in order to ensure that your kiln is operating correctly and safely.

Conclusion

Things to keep in mind when using a lumber kiln include ensuring proper ventilation, wearing protective gear and clothing, and following all manufacturer instructions. Additionally, it is important to monitor the drying process closely and make any necessary adjustments as needed to ensure that your wood dries correctly.

Finally, you may want to consult with a professional lumber kiln manufacturer in order to ensure that your kiln is operating correctly and safely. Check HeBei ShuoWei’s website for more ideas or contact us if you need help with kiln-drying!