Kiln Drying Wood in Oven

Shuowei embraces sophisticated manufacturing equipment and possesses professional production lines to ensure the high quality of vacuum dryer machine. Shuowei wood drying kilns are exported to China and more than 80 countries and regions.

- Prevent Damages

- Easy Usage

- Fast Drying

- Environmental Safe

Kiln Drying Wood in oven

Drying wood in a kiln helps keep the wood from problem such as shrinking and cracking. Dried wood that has shrunk and cracked is much harder to install and can cause a lot of unnecessary headaches during and after the installation process. Removing the wood’s moisture in a kiln ensures the wood remains a consistent size even after it has been installed. This very essential especially for wood installation such as wood flooring and wood furniture.

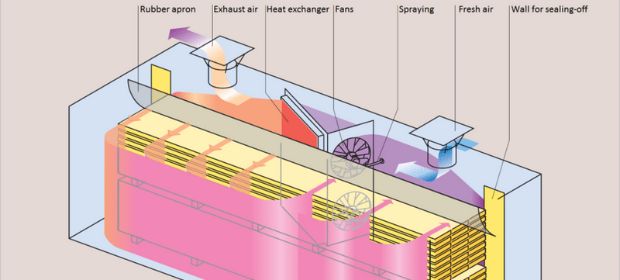

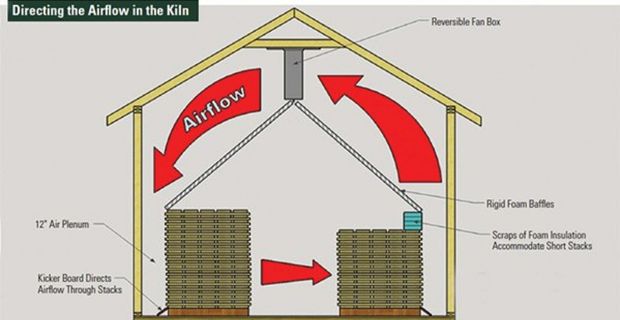

The kiln process involves the drying of wood in a chamber where air circulation, relative humidity and temperature can be controlled so that the moisture content of wood can be reduced to a target point without having any drying defects. Shuowie’s products are the best option when it comes to finding the most reliable wood kiln.

Shuowei Products

Small Wood Drying Kiln

This wood drying kiln has a volume of 4.4 cubic meters and can hold wood up to 4 meters long. This is a small capacity wood dryer suitable for the wood industry such as small sawmills, furniture makers, guitar makers and carpenters. Despite being small, this kiln has the same feature as the other bigger wood kiln.

Wood Drying Kiln

This wood drying kiln has volume of 6.6 cubic meters and can hold wood up to a length of 5 meters. Small and medium-sized wood working shop, sawmills, and other businesses typically use it. Choosing our product is best decision you’ll ever have. This drying kilns are the most advanced drying technology in the world.

Vacuum Kiln

This wood drying kiln has a volume of 8.64 cubic meters and can accommodate up to 6 meters of wood. This is a medium capacity dryer for the wood industry such as medium-sized sawmills, furniture manufacturers, etc. The most advanced wood drying equipment and achiever in China and even in other countries.

Dehumidification Kiln

This wood drying kiln has a volume of 10.08 cubic meters and can hold wood up to 7 meters long. This is a medium-capacity dryer for the wood industry such as medium-sized sawmills, furniture manufacturers, etc. This is a multi-purpose machine: (1) can dehumidify; (2) can dry. This double the drying speed of the wood.

High Frequency Vacuum Kiln

This wood drying kiln has a volume of 12.48 cubic meters and can hold wood up to 8 meters long. This is a high-capacity dryer suitable for the wood industry such as large sawmills, flooring plants, furniture manufacturers, etc. This wood drying kiln with large wood capacity reduces the storage of wood drying materials and thus reduces running costs.

Custom Wood Drying Kiln

This wood drying kiln depends what you are needing and what’s the best kiln for your big woods. There are many customers with different space sizes in their plants and different usage scenarios, in order not to affect the users’ usage. That is why Shuowei offers this type of kiln. we are the direct manufacturer and can do this easily.

Product advantages

Prevent Damages

We ensure our costumers that theres no suffering from cracking and bending.

easy usage

PLC control system and Pneumatic system make the machine easy to operate.

Fast Drying

Has temperature gradient of internal high and external low and then vacuum pressure make water drain out very quickly

Environmental Safe

No usage of oil. No emitting of toxic smoke. Being mother earth friendly.

where can we use our kiln-dried woods?

Kiln dried wood can be used in so many ways, such as for construction and any wood working projects. Kiln dried wood is the go to for construction. Dried lumber is also used to make furniture as it lasts longer and has relatively high strength, so products that are made from this kind of woods are effectively live and can use much longer.

How does this Drying kilns dry our woods?

Any process of kiln drying (vacuum, conventional or solar) it is controlled by three factors – relative humidity, air

flow and temperature. Air flow around the wood is the most important, why? because if there isn’t it, its surrounding air will rapidly become saturated that moisture loss to the atmosphere will stop. Simply, as water reaches the surface of the wood

the rate or volume of air passing across its surface must

be sufficient to carry away the saturated air .

Two methods in drying woods

Drying of woods is either by this two basic method:

• Kiln drying – where moisture is extracted by

artificially controlling its environment under

exaggerated conditions using enclosed chamber.

• Air drying – where the lumber is allowed to dry itself naturally from its ‘green’ or unseasoned state.

Company Advantage

Shuowei has been devoted deep into the vacuum wood drying field for over 30 year, we pay much attention on improving the operation and developing the designs.

When making furniture, floors or wooden handicrafts, wood drying is an indispensable process; the purpose of drying wood is to reduce unnecessary troubles in later use, in order to ensure that wood can achieve fast and effective drying results, Shuowei drying kiln has concentrated on the high-frequency and vacuum drying technology, so that the wood drying kiln combining high-frequency vacuum has been developed, and it has been highly praised by customers in various countries, saving customers more time and money.

How the product works

This one of the most specific thing that is working in the processes in wood drying using – the evaporation of water from the inside of the wood or wood’s inner layers to the outer surface. Water will begin to move to the surface as the wood dries. As this continues, the moisture content difference between the wood surface and its interior will be dependent upon the rate of evaporation verses the rate of water movement through the wood.

drying effect

Burning wet wood will lead to an increase in smoke and emissions and produce little heat. It will also lead to a blackening of the stove glass and a build-up of soot in the chimney. Using dry wood also means that fewer logs are needed to produce the same level of heat. This saves money and reduces emissions because less wood is being burnt. That is why Shuowei released and launched our series of wood drying kilns.

Drying woods Step by Step

Step 1: Mill your woods

The first step here is to mill your wood. Cut down the tree logs using professional chainsaws just like those used in sawmills, together with other necessary equipment in order to have wood of required size and shape. Also, proper sizing of the logs is a very important step in getting the woods to dry perfectly.

Step 2: Know the Moisture Content

However, to make sure your wood is at the perfect moisture level for woodworking, you’ll need a small tool called a moisture meter, which would help you determine the accurate moisture content of the wood. If the moisture content of the wood is higher than that, then it must be dried again to attain this level.

Step 3: Air Drying

This simply means exposing your woods to natural air and sunlight to achieve drying. You can start by doing this for a few months in order to naturally get rid of the first bit of water. This process is usually important and produces better results. Ensure that you stack up the woods with lots of stickers or spacers under the natural air and sunlight, to allow for a good flow of air

Step 4: Use the Kiln Drying Wood

The kiln performance can be effectively monitored by taking kiln samples which should be selected from the kiln during stacking. The number of samples selected usually depends on the condition of the wood being dried as well as the drying characteristics. The type of kiln used is also taken into consideration.

Step 5: Acclimating the Wood

After attaining the suitable moisture content, take the wood into your workshop and leave it to acclimate for a few weeks before you start processing it. This would be tken for less than a week.

Step 6: Making Furniture

By following these procedures, your wood should be ready for making the furniture that you desire. Using this unique wood often presents you with the opportunity to actually showcase that unique woodwork that you can be proud of harvesting in a sustainable manner.

Step 7: Sell or use the finished products

Now that you are done with your long journey together with the woods, it’s time for you to decide whether you sell profiting by it or cherish it with you inside your home. Regardless of your decision, happiness is when you see the outcome of your effort, time and hardwork for weeks. Be sure that the finished products are usen reasonable.

Why Choose Us Shuowei?

Shuowei company has rich of experience. We are focused on the wood drying industry for more than 30 years, Shuowei has mastered the drying methods of various wood species, and has most collected comprehensive drying data.

our service

Customized services: According to the customers’ requirements, we can customize the exclusive equipment which is suitable for the work conditions and needs.

After sales service: Super long warranty, free replacement of accessories within the warranty period, free after-sales service for life, 24-hour after-sales service all day, and solve after-sales problems anytime and anywhere

Have more questions please contact us

Bottom FAQ

Compared with the air seasoning and conventional kiln drying, high frequency vacuum wood dryer kiln has greatly shorten the drying circle, you do not need wait years or months to get quality dried wood any more. The average drying time is 4-15 days to finish whole dry process.

If you plan to dry 50 CBM ash slab with thickness of 100mm per month and initial moisture is 30-40%. According to the data, it will take 5 days to reach 8% MC. So In a month, you can finish 6 wood drying cycles.Then we could know the net capacity of high frequency vacuum wood dry kiln should be 8 CBM (50CBM/month ÷ 6 monthly cycles = 8.3cbm), Based on this, it is easy to find that SW-8.0III is suitable for you. The capacity of SW-8.0III model is 8.64cbm

The warranty of Shuowei high frequency vacuum wood dryer kiln is one year since received the dryer. If any part damaged because of non-human factors,we will send new parts for replacement free.

Spark protection is one of our kiln’s self protection program, if some wrong connection bring spark inside of the high frequency vacuum wood dryer kiln, the kiln will power off immediately. Another reason it won’t catching fire is the vacuum, inside of the wood dryer kiln is a vacuum condition, even if it is sparked, it won’t fire. Because no oxygen. So no worry about the fire, if sparked, the operator just need check the connection will be ok.

The vacuum chamber is make of stainless steel, so it is very tough, and the daily maintenance work is just some cleaning after finishing one drying cycle. The main electronic components are all using top brand (like Schneider) and the high frequency generator is with a self-protect programs, so the maintain costs could be almost ignored.

After placing order, we need 25 days to finish the production and testing of the high frequency vacuum wood dryer kiln. and then we will arrange the latest shipment. If you have plan to purchase this high frequency vacuum wood dryer kiln from us, please contact us ahead of time, we do not have many ready stocks for such machines for requirements varies from different clients.

The heat in the kiln dries off the resins in softwoods. Air-drying is a natural process that can take up to 8 -16 months, depending on the species of wood. Kiln-drying, on the other hand, usually takes 6 – 8 weeks. This process doesn’t introduce any internal tensions in the wood.

There are many reasons why wood suppliers like Northern Log Supply believe kiln-dried logs are better than air-dried logs. Because of the high heat, kiln drying ensures that all insects, eggs, mold, and fungi in the wood are killed and dries off the resin, which would otherwise turn to liquid at room temperature.

Drying wood in a kiln helps keep the wood from shrinking. Reclaimed wood that has shrunk is much harder to install and can cause a lot of unnecessary headaches during and after the installation process. Removing the wood’s moisture in a kiln ensures the wood remains a consistent size even after it has been installed.

Untreated pine or spruce (whether heat-treated or kiln-dried) are good, inexpensive options. Unlike pressure-treated lumber, untreated or heat-treated wood contains no questionable chemical compounds that may leach into the soil within the bed.

We'd like to work with you

If you have any questions or request a quote, please send us a message. Our experts will reply you within 24 hours and help you choose your suitable wood drying kiln, and can also help you solve wood drying problems.