China is the second largest timber consumer and the largest timber importer in the world. Therefore, it is a major trend in the future to improve the wood utilization rate, enhance the wood utilization efficiency and reduce the wood consumption. Wood drying is one of the effective measures to improve the utilization rate and benefit of wood.At present, with the rapid development of wood drying in China, there are also some problems that can not be ignored, which can be summarized as follows

1.The drying capacity continues to increase, but the drying ratio is low, and there is still much room for development

The amount of artificially dried wood in China is about 13million M ³ The above accounts for only about 30% of the total amount of wood to be dried, and the proportion in developed countries reaches 60%~70%, which shows that the drying proportion in China is far from that in developed countries, and there is still much room for the development of wood drying industry.

2.Conventional steam drying is still dominant, but the drying methods tend to be diversified

There are many kinds of wood drying methods, but conventional drying is dominant because of its mature technology, simple operation, easy to master drying characteristics, strong adaptability, large loading volume, fast drying speed and many other advantages. In recent years, with the progress of science and technology, drying methods tend to be diversified, such as dehumidification drying, solar drying, vacuum drying, microwave drying, high-frequency drying and other methods have been applied to various wood drying.

3. Drying equipment has made great progress, and there are many problems to be solved

Nowadays, with the development of the application of clean energy and heat recovery technologies such as high-frequency drying, microwave drying, heat pump dehumidification drying technology based on electric energy, and solar wood drying technology in wood drying, the production cost is reduced while reducing environmental pollution.

4. Research and standards related to drying standards still need to be deepened

The drying standard is the guide for wood drying production and the main basis for process operation. According to the characteristics of different tree species, specifications and uses, domestic wood processing enterprises need to perfect and unify the wood drying standard.

5. The drying quality has been improved. However, due to the large number of difficult to dry trees, the problem of drying quality is prominent

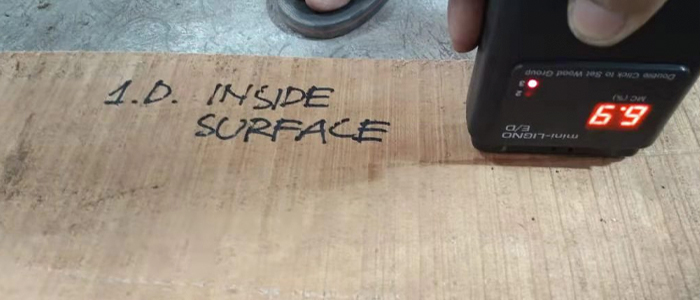

Due to the large geographical area of China and the large difference in the balanced moisture content of wood products in different regions, there will be many product quality problems if the moisture content of wood products is not properly controlled in production. In addition, there are many difficult to dry trees, which will have uneven moisture content, more cracks, larger deformation, local color darkening, internal cracks in local wood piles, and long drying cycle during drying, which all cause serious waste of wood.

6. Wood drying has high energy consumption and heavy pollution, and the application proportion of energy conservation and environmental protection is low

At the present stage, coal and wood processing residues are the main fuel for wood drying in China. The high drying energy consumption not only increases the product cost, but also increases the smoke and exhaust gas discharged from boilers and drying rooms, resulting in environmental pollution

Facing the problems and development challenges in the wood drying industry, to improve the development level of the wood drying industry, we need to start from the following aspects:

1. Restrict the use of high energy consumption and high pollution drying equipment, and increase policy and financial support for energy-saving and environmental protection drying equipment.

2. Give full play to the leading role of industry associations to promote the healthy development of wood drying industry.

3. Pay attention to the research, development and use of energy-saving and environment-friendly wood drying technology and equipment.

The application of high-frequency and microwave technologies in wood drying has improved the quality and speed of wood drying and reduced environmental pollution.

High frequency vacuum drying is to make the molecules in the wood run at a high speed through dielectric heating, generate heat for rapid heating, and then quickly absorb water for drying through vacuum negative pressure, which is more stable, fast and of good quality

In the thermal process of rapid drying, the wood was dried with a temperature gradient of high inside and low outside. It can effectively guarantee the quality of the wood. During the drying process, it can compress the wood, prevent deformation, and play the role of wood leveling. It can effectively improve the drying quality and work efficiency.