Drying can affect various wood properties such as its structure, moisture behavior, and mechanical properties. Understanding the effects of drying on the complex interactions of the wood ultrastructure, and the resulting properties are crucial for the proper conservation of waterlogged wooden artifacts. This was the purpose of this study. It focuses on the effects of drying conditions on the cell wall structure, dimensional stability, and hygroscopicity in degraded archaeological wood.

Why dry wood?

The answer to the question, “Why dry wood?” is simple: “… To make money! If it is not profitable if it isn’t, then we don’t usually do anything. Let’s look at what happens after trying to find out what makes a labor-intensive, energy-intensive, and time-consuming procedure profitable.

Wood is a biomaterial that contains large amounts of water when it is in its natural state. Many of the wood’s properties and characteristics will change as it dries to a moisture level (MC) that is in equilibrium with its environment.

- The lumber dryer will cause most of the shrinkage in wood that happens when it dries to its in-use MC. This is in contrast to the manufacturing product. Wood shrinkage and swelling can be frustrating for consumers, so drying reduces it to a minimum level.

- Dry wood is unlikely to develop new cracks or checks or splits.

- Dry wood below 22% MC will not cause decay, mold, mildew, or stain. Lower MC levels mean that there isn’t enough moisture to allow the fungi responsible for decay, mildew and so forth to grow.

- Dry wood weighs less than wet wood. Dry wood weighs nearly half as much as wet wood for many species. An example: An “18-wheeler”, which can carry 7500 BF green oak, but not exceed load limits, can also haul 12,500 BF dried lumber.

- Dry wood is almost twice as strong as green wood and twice as stiff.

- If dry wood is not too dried, it will be faster to glue, fasten better and work better with machines than wet wood.

- Fire retardants can be used more effectively on dry wood than they can on wet wood.

How dry should wood be?

Wood should be dried to a moisture content of two percent or less than its in-use MC. In-use MC for furniture, cabinetry, and millwork is between 6-8% (the equivalent to 30 to 45% relative humidity), which is typical for North American interior climates. For dry humidities (such as those that occur in winter in heated buildings not humidified), and wetter humidities (such as along the Southern or West coasts), adjustments must be made.

Wood for outdoor use is usually dried to higher MCs, 12 to 16% MCS. For bending, wood should be dried at 25% MC for severe bends, and 18% for mild ones. Softwood construction lumber (2×4, 2×6, etc.) It is typically dried to a maximum of 19% or 15% (or 12% MC) according to the American Lumber Standard. In-use MCs are determined by the relationship between wood moisture content and humidity.

The temperature has no significant effect. These values were derived from spruce:

| Relationship between RH and EMC at Room-temperature |

| RH % | EMC % |

| 0 | 0 |

| 15 | 3.5 |

| 30 | 6 |

| 50 | 9 |

| 65 | 12 |

| 80 | 16 |

| 90 | 20 |

| 95 | 24 |

| 100 | 28 |

EMC (Equilibrium Moisture Content) is the numerical value for the in-use MC of the spruce at equilibrium with indicated humidity. Most wood species have the same values as spruce. They vary by less than 2% EMC below 80 percent RH. Certain species, particularly those that have a lot more extractives, will show higher RH values than others. The EMC for these species is usually lower than for spruce.

Incorrect MC is the leading cause of manufacturing defects in cabinet and furniture plants. This accounts for approximately 85% of all the defects I have been called upon to correct. It is important to pay attention to the humidity (not temperature) where lumber is stored, manufactured, and shipped to ensure that the MC of dried lumber or wood products is maintained close to its final, in-use EMC.

Wood drying methods

The main purpose of drying lumber is to make a profit. Therefore, lumber must be dried without any development or degradation. Splits, checks, and warp are all examples of degradation. Degrade often exceeds all other drying costs. Operating a dry kiln using oak lumber costs $3 per MBF. This means that if you save one day of drying time, your operating costs will be $3 per MBF. However, if the drying time is faster (and this is a very small amount of degradation), then there are no savings. There are five main methods of drying currently in use: air drying, forced air air-drying (including warehouse pre-drying and dehumidification drying), low-temperature dry (including both warehouse drying and dehumidification drying), traditional kiln drying, and high-temperature dry. Each method has its own characteristics that can affect the performance and cost of different species and thicknesses. Below are the characteristics of all except high-temperature drying. Hardwoods cannot be dried at high temperatures. Vacuum drying is also an industrial option, particularly for square drying and smaller production needs.

Air drying

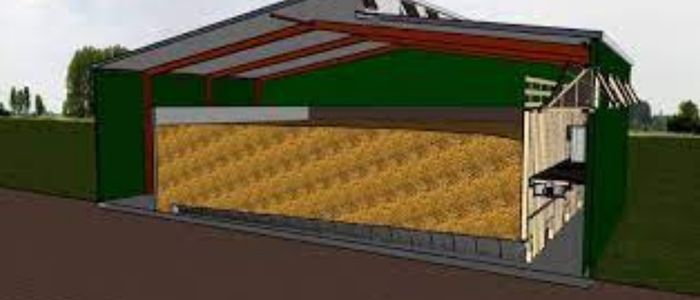

refers to the exposure of lumber outside to environmental conditions without any control over velocity or heating. You can protect the lumber from sunlight and rain by placing a small roof over each pile or by using sheds. Sheds can reduce the risk of lumber getting damaged. This method is expensive because of the high degradation risk. Shutters can be used to reduce degradability and allow species like oak to be dried economically.

Forced-Air Drying (or Fan Shed Drying)

Forcing-air air drying is where lumber is dried by drying it in a conventional manner. The lumber is then placed under sheds to dry.

The sheds are equipped with a lot of fans that draw outside air through the lumber pile. With an adequate roof, the sun and rain are kept from the lumber. This allows for fast drying without any degradation. Air velocity is approximately 700 fpm. The maximum airflow path is 20 ft. For every 6 MBF dried, the dryer will typically use 1 hp fan power. This drying method is particularly attractive for drying thickened and low-degrade species.

Pre-drying Low-Temperature Warehouse

A warehouse dryer can be a large structure that holds up to 1.5 million BF of stickered lumber. The lumber piles are cooled by fans that circulate air. Steam heating coils are used to heat the wood. A fan-powered exhaust system provides ventilation.

There is usually no humidification system, other than the moisture from the dried lumber. This drying method is popular for oak and other species that are difficult to dry.

Drying of Low-Temperature Dehumidification

Dehumidification drying can be described as kiln drying. A dehumidifier removes moisture from dryers by condensing it on cold coils. The heat released from the water condensation is used to dry the lumber. The dryer is extremely energy-efficient because of the recycling.

The heat pump can be operated electrically. The heat pump typically produces 1 hp per MBF of lumber. Smaller sizes are better for drying slower species, while larger sizes are better for drying faster species. To avoid electrically generated heat being wasted, the building is often well insulated. It may be either a prefabricated aluminum or wood-framed building.

Normal Temperature Drying or Conventional Temperature

This method is the most reliable and tried-and-true way to dry lumber. It has been used for many decades for both softwoods and hardwoods. If the equipment is properly designed and operated, quality is almost always excellent.

Lumber is dried and stacked before being placed in a kiln. The steam coils heat the load and circulate air through it. Vents are used to exhaust excess moisture. Steam spray can be used to add moisture. Most modern kilns are made of aluminum, although you may occasionally see a masonry structure. To conserve energy and prevent uneven drying temperatures, insulation should be at least 2 inches thick.

Take Away

To increase the value of your wood, you need to choose your drying method carefully, to dry your wood perfectly and add some value to it. If you are looking for a drying method that will surely increase the revenue of your wood business. We offer a high-frequency drying machine, it dries the wood perfectly and has many benefits for the wood. It will increase the value of your dried wood.