Recently the vacuum wood drying is becoming more and more popular, There will be a vacuum chamber in the vacuum drying system, and its need for the temperature could be as low as 30-50 ℃. Anyway there still need a heater to offer energy to the water inside the wood.

So what is the best way to heat wood in vacuum wood drying kilns?

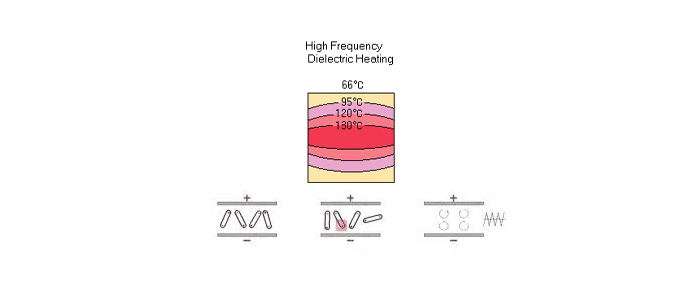

The answer is the high frequency, High frequency is also called radio frequency, this technology is a kind of direct heating. The principle is using the wood as a medium, When giving the two pieces of metal plate voltage, an electric field is created between them. Then water molecular in the wood and between electrodes will be polarized by the alternating magnetic field and move in very high speed rapidly. The impact and friction (billions of times per second) among water molecules creates heating in very short time.

To be frank ,High frequency is not the latest technology in the wood drying field, Ever since 1980s, people began to try a better way to solve the wood drying problem, because it is the most important and costly process in the wood applications, and now high frequency is a quite mature method to heat the wood.

So when you put wood in the vacuum wood drying kiln, the 6.78 MHz waves can penetrate wood deeply and dry wood from core to wood surface wholly and uniformly from the ever beginning , you will find the core is with a higher temperature than the surface, this is the most ideal status we want to get.

Even it is a much better way, at the every beginning, this heating is not so popular, because compared with the traditional boiler, it is purely powered by electricity, which is more expensive, meanwhile the boiler could burn the sawdust and wood waste to get hot steam, which will lower the cost. And other concerns are to apply this technology, we need a special chamber and the capacity is small, the high temperature in the wood core may bring some defects.

It come to be applicable when boiler is under more and more strict control for environment pollution and high risks, And now vacuum drying system is becoming more and more popular. You will find vacuum drying well eliminate the disadvantages of the high frequency heating.

So let see what it will bring us, if we use high frequency in the wood drying instead of the traditional steam and heating plates.

Comparison For Different Heating Methods In Vacuum Wood Drying

| Items | Traditional Steam Heating | Metal Heating Plates | Metal Heating Plates |

| Drying time | 14 days | 5 days | 4 days |

| Defect factors(%) | ≤13% | ≤8% | ≤1% |

| Space utilization(%) | 60%-80% | 40%-60% | ≥90% |

| Energy efficiency | 30%-40% | 50%-70% | 60%-80% |

| Production Cost(USD/BF) | ≤0.06 | ≤0.05 | ≤0.04 |

| Notes | |||

| 1.The test results are based on 2 inches Oak slab with initial MC 50% and finish MC 10% | 2.Defects including clear discolor, deformation and crackings, please contact us for more information | 3.The cost of the three heating methods are all based on powering by electricity,and the electricity price is referring to that of New York City the US |