I’m excited to share the continued success we’re having with our high frequency (HF) vacuum kiln in Indonesia! And the results have been truly exceptional. New technology is changing the way people dry and process mahogany and teak wood. This is providing clients in the area with better quality and efficiency.

The Beauty and Challenge of Mahogany and Teak Wood

Indonesia is blessed with rich, diverse forests, covering about half of the country’s land area. Among the many valuable species, mahogany and teak wood are true gems. Teak’s durability and resistance to pests and water make it ideal for high-end furniture and construction. Mahogany, with its rich color and fine grain, is equally popular. However, drying both woods presents unique challenges.

Teak is hard to dry evenly because it has a lot of oil and is dense. Mahogany can crack or warp if not handled properly. It usually takes several months to dry using conventional kiln. That’s where our HF vacuum kiln makes a difference.

Tackling Drying Challenges with Cutting-Edge Technology

We designed our kiln with these challenges in mind. At this time, our vacuum kiln drying teak and mahogany logs with moisture content ranging from as low as 10% to as high as 80%, and thicknesses between 30mm and 60mm. The kiln’s advanced touchscreen controls and precise management of temperature and vacuum conditions allowed us to dry the wood uniformly to a stable 6-8% moisture content in 8 days. Even with such varying initial moisture levels, there was no cracking, no warping—just perfectly dried wood.

The key to our success is our HF-vacuum technology. It uses high-frequency waves to generate heat within the wood and creates a vacuum environment that lowers the boiling point of water. This process speeds up drying and ensures an even result. This technology minimizes the risks that typically come with conventional drying methods and ensures that every piece of wood meets the highest quality standards.

Hearing from Our Satisfied Customers

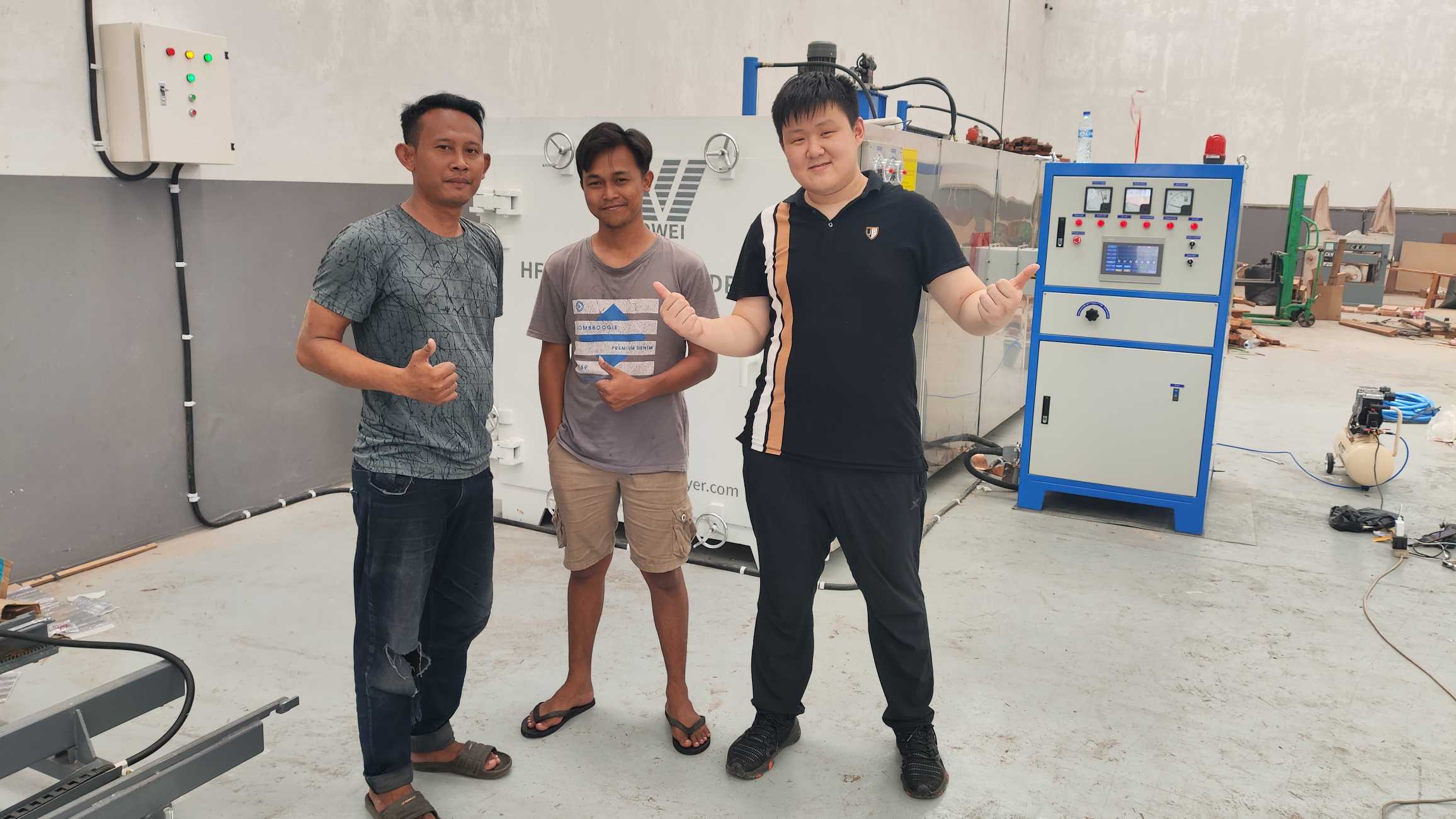

What makes this achievement even more rewarding is the feedback we’ve received from our customers in Indonesia. They are impressed with how well the kiln handles different moisture levels and consistently dries wood of high quality. Knowing that our equipment is making a real difference in their operations is incredibly satisfying.

Continuing to Lead the Wood Industry

Our multiple installations in Indonesia reflect not just our commitment to innovation but also our dedication to supporting sustainable wood processing practices. We’re proud to be a part of preserving Indonesia’s rich forest resources, ensuring that the beauty and value of teak and mahogany can be enjoyed for generations to come.

lf you’re looking to enhance your wood drying process with proven technology, we’re here to help you every step of the way. Contact us to get the best equipment and expertise in the industry.