Vacuum Kiln Manufacturing Supplier

Shuowei‘s vacuum kiln is now one of the most advanced wood drying equipment in China and has achieved remarkable results in the field of vacuum drying of wood.

wood dealer

Furniture Factory

Shipbuilding Deckyard

wood craft producer

What is vacuum kiln drying

The more advanced vacuum drying kiln uses a vacuum to lower the boiling point of the water, so that the moisture in the wood evaporates from the inside out, and the top of the wood is equipped with a hydraulic device, which incidentally plays a role in straightening the wood. The wood will not be bent or cracked.

Model series of vacuum kiln

The small vacuum kiln can also be loaded with large quantities of wood for drying; it has a small footprint, does not take up much space and can be easily transported in containers

The Indonesian customer wood furniture factory has a large demand for dry wood, so two vacuum kilns operate at the same time, which can efficiently meet the market demand.

Vacuum wood drying equipment covers a small area, saves space, has a large wood loading capacity, and can dry a large amount of wood at once.

The 6 cubic metre vacuum kiln can be loaded with timber up to 5 metres long; This capacity kiln is generally suitable for small sawmills or furniture factories

The 10 cubic meter vacuum kiln can be loaded with timber up to 7 meters long; The vacuum kiln is able to dry thick wood because the high-frequency waves pene。

According to the needs of different customers, we can ask you to customize your own wood drying kiln. Solve the wood drying problem for you.

The benefits of vacuum kiln drying

Timber does not crack

High-frequency vacuum drying is heated from the inside out, while heating is more uniform, fast and less prone to cracking and bending.

vacuum kiln cost

By drying the wood quickly to get the finished product, the sawmill or furniture factory can have more working capital and save more money.

fast drying time

Even more time can be saved by drying at low temperatures without oxygen to speed up the drying process and improve the quality of the wood.

Environmental friendly

The wood drying process has no impact on the environment, no harmful substances are discharged, and it is safe and environmentally friendly.

good effect

The wood is dried by vacuum kiln, and the moisture content is consistent; the wood does not crack or bend, effectively killing the Worm eggs

How to use a vacuum kiln

The vacuum kiln is shipped to you quickly via sea container.

Setting up the vacuum kiln according to the installation instructions once you have received the equipment.

Prepare the wood to be dried and carry out a moisture content test before drying, this is for the best comparison with the moisture content of the dried wood.

Load the prepared wood flat on the timber cart , place it in the vacuum box and start the drying process.

After a period of drying, the water evaporates from the timber and is then released;

when the drying is complete, the timber is pulled out and the moisture content of the dried timber is tested.

Detailed operational details will be taught by our professional engineers

Main components of vacuum kiln

Main body of vacuum kiln

The reason why our vacuum kiln cabinet is square is based on our many years of wood drying experience. First, the square has stability and will not collapse. Second, the square vacuum kiln can load more wood. Third, the square is easy to operate in use.

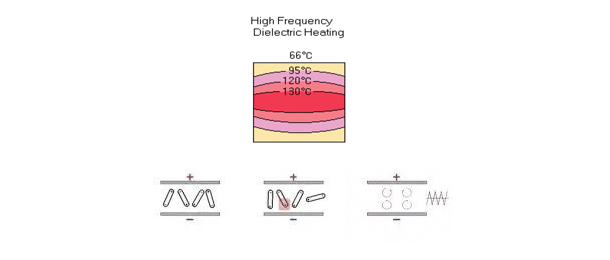

High Frequency Generator

The vacuum high-frequency generator is the core technology of the vacuum kiln. It is heated by a high-frequency medium. The principle is to use an electric field to make the wood moisture at a high speed. It will generate heat from the inside to the outside. It is a direct heating method. The temperature inside and outside is uniform.

Cooling Tower

The cooling tower is an automatic cooling system. Hot steam will appear during the heating process of wood. Its function is to separate the water and steam, and then discharge the moisture in the wood.

Hydralic Pressure System

There is a set of hydraulic device in the vacuum kiln. We all know that wood will deform and warp when heated. This device can solve the problem of wood deformation. This hydraulic device can provide 6-8 tons of pressure.

Motor Drive Timber Cart

Automatic feeding device, when we investigated the wood drying market, we found that it is very laborious and inconvenient for workers to load and unload wood. Our team has developed an automatic feeding device, which can greatly reduce labor.

Pneumatic valve & Stainless Steel Pipes

The reason why our drying kiln is of good quality is because the stainless steel vacuum pump and solenoid valve are used, and all the pipes are made of 304 stainless steel, which ensures the safety and reliability of the user in use.

Comparison of vacuum kiln and ordinary drying kiln

Vacuum drying kiln

Vacuum kiln is currently the most advanced wood drying equipment on the market, and it is also the most environmentally friendly equipment. It only needs electricity, no boiler, and is very simple to operate.

- Flexible operation: automatic feeding machine, which can be moved at will.

- High efficiency: After our experimental comparison, the vacuum kiln is between 10-13 times faster than the ordinary drying kiln.

- Good drying effect: no cracking and deformation due to uniform heating.

ordinary drying kiln

Ordinary drying kilns were produced in the late 1990s, generally burning coal, which is not environmentally friendly.

- Operation: The operation is complicated and requires manual loading and unloading of wood.

- Inefficiency: It takes more than 20 days to dry a batch of wood.

- Drying effect: The traditional kiln radiates heat to the kiln chamber pipes, which is unevenly heated and easy to crack.

Working principle of vacuum kiln

Working principle of vacuum kiln: using high-frequency electric field as the heating source, it radiates evenly on the wood, penetrates deep into the wood, and directly heats the water.

The wood itself or other non-polar materials do not receive the high frequency electric field, the electric field penetrates the wood, and only the friction between the water molecules generates heat during the drying process.

Advantages of vacuum kilns

- Faster drying gives more liquidity

- Consistent and uniform moisture content of the dried wood

- No cracking or bending of the wood

- Easy to operate, reducing labour costs

- Effective in killing insect eggs in the wood

Vacuum kiln drying wood results

1. Mahogany: Thickness 50-70mm, the Initial MC between 40%-50%; Target MC 8%-10%, The drying time is 5 days

2. Black walnut: Thickness 75-100mm,the Initial MC between 40%-50%; Target MC 6%-8%,the drying time is 8 days

3. Eastern cottonwood : thickness 70mm, Initial Moisture:75% ; Final Moisture:8%, the drying time is 4 days

Certificate in Modern Wood Drying Kiln

Our vacuum kilns have passed SGS, CE, ISO9000 and other certifications. Strictly control product quality.

Vacuum kiln case

shuowei specializes in manufacturing wood dryers for 32+ years and sells them all over the world.

shuowei vacuum kiln drying service

1、A team of professional engineers, without any language barrier, to provide you with professional technical services.

2、The most suitable equipment can be customised according to the size of the property and the wood size of the customer’s place of use.

3、Safe and professional shipment, with tight reinforcement of all parts to ensure that the equipment is not damaged during transport.

4、24-hour service available 24/7 to help you solve any problems.

5、Provide product life-long after-sales.

6、Provide free replacement service for accessories

7、Provide online guidance

8、Support multiple payment methods(Prepaid 30% available)

Have more questions please contact us

vacuum kiln:The Ultimate Guide

Common wood drying kilns are: radio frequency vacuum drying kiln, microwave vacuum kiln, steam vacuum kiln, high frequency vacuum kiln, solar drying kiln, etc.

1 、Atmospheric dryness

2 、chamber dry

3 、Vacuum drying

4、High frequency vacuum drying

5、natural air drying

This is a very interesting questions when we are trying to get better turnover and healthier cash flow in the wood drying field.

What we need make clear firstly is that the wood drying is an indispensable process in the usage of wood sources, when you get the raw materials from the forest, the water content in these wood are as high as 60% or even 100% more, they are easy to deformation and prone to pests and fungi, And the cost to transport these wood will be much higher than the dried one because the transportation is priced by weight.

And Then comes the question of how to dry the wood? There are many existing ways, like air drying, kiln drying , vacuum drying, high frequency drying etc., they are all of different features and are applicable for different cases, different people will choose different methods for their purposes, but one thing that is always a big concern and easy to compare is the drying speed, just like the other products, the best production mechanism is that you could get the finish product quickly, sell it and get back the investment & interests.

What is the fastest way to dry wood? And how fast is it?

As of the nowadays technology, the high frequency drying or Microwave Drying is the fastest way to dry the wood,the working process will be like that High frequency generator generates electromagnetic fields between two electrodes through three phase alternating current where the wood are loaded, In this field, water molecules are polarized – rotated – heated by friction. The heated water then will be vaporized and comes out of the wood.

It is totally different from the traditional kilns, for which you need first heat the air or the metal plates and then conduct the heat to the wood, it is a direct heating methods which works on the water inside the wood.

Such heating method will greatly shorten the drying process, and it will only take several days to dry the green wood to wood with below 10% water content. When we are talking higher temperature and higher airspeed in the traditional kilns to faster the drying speed, this kind of high frequency drying already totally redefine the drying fast to days, which may takes weeks before.

Anyway, there maybe different need of wood drying, like for furniture and fences , the MC results needed are different, for woodwoking and firewood, the quality requirement are not the same, but in every aspect and work conditions, High frequency drying are the fastest wood drying methods, It’s an innate advantage.

Get in touch with Shuowei high frequency wood drying kilns! Our team are experts in wood drying applications. We understand the demand of the industry and need for easier faster and higher quality drying solutions.

High frequency vacuum drying is the advanced wood drying technology. It is using electricity filed principle to make water molecule friction get heat. it is kind of directly heating. That will ensure wood inside and outside heating uniform.At a vacuum water boils at a lower temperature.

Ordinary wood is generally dried in 3-5 days

The wood will deform and warp after high temperature. This is a very tricky thing, but our vacuum kiln solves this problem perfectly. There is a hydraulic system inside our vacuum kiln, which can provide 6-8 tons of wood stacking pressure, so this problem is solved.

shuowei vacuum kiln for sale, high frequency vacuum dryers, wood dryers, dryer accessories, sheet metal casings, etc.

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right HF wooddryer you want.