High frequency and microwave technology are widely used in various industries, such as the food industry, material chemical industry, pharmaceutical industry, mineral mining industry, ceramic industry, laboratory analysis, natural rubber processing, and so on.

High frequency and microwave technology have many excellent properties such as fast heating speed, uniform heating, efficient use of energy, rapid process control, and help to improve product quality, and their applications in the home manufacturing industry are gradually enriched, especially in wood Application in drying, plywood splicing, wood frame bonding, curved wood forming, wood door pressing and other processes. Although the two technologies are similar in working principles, performance in various aspects is not the same.

01 What are high frequency and microwave

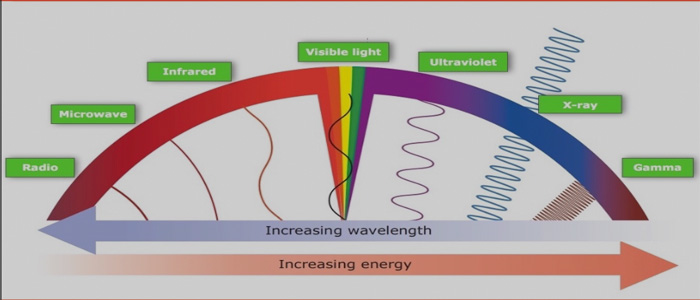

Both high frequency and microwave are electromagnetic waves, and their application methods in the home furnishing manufacturing industry are mainly focused on heating and drying, whether the drying is moisture or glue. Therefore, the discussion is mainly based on high-frequency drying technology and microwave drying technology.

01-1 Development of high frequency and microwave drying

In the early 1960s, scholars from the United States, Japan, Canada, Germany, and other countries took the lead in researching the use of high-frequency and microwave technology to dry wood. The experimental results show that this is the most effective rapid drying method.

China began to carry out research and promotion of wood high-frequency and microwave drying technology in 1974. The study found that this technology can achieve better results in drying precious wood with hardwood.

01-2 Working principle of high frequency and microwave drying

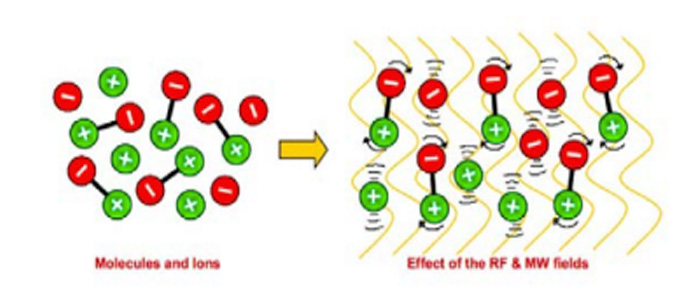

The working principle of the two is to use the principle of dielectric heating and drying. Both use wet wood as a dielectric and place it in an alternating electromagnetic field. Under the action of the frequent alternating electromagnetic field, the polarized water molecules in the wood rotate rapidly. They rub against each other and generate heat, which heats and dries the wood.

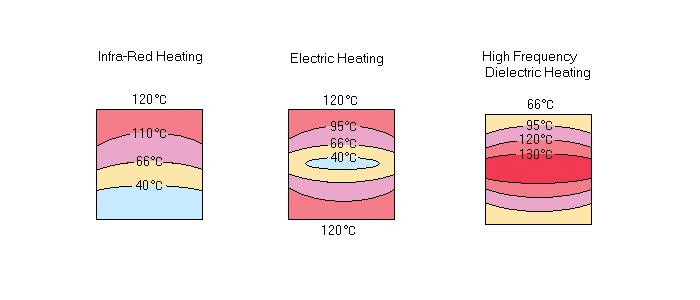

In conventional drying, the drying medium transfers heat to the surface of the wood in the form of convection or heat conduction, and then transfers the heat from the surface of the wood to the interior of the wood in the form of heat conduction, so that the overall temperature of the wood increases. The difference is that when high-frequency and microwave drying and heating, the heat is not transmitted from the outside of the wood to the inside but occurs directly inside the wood through the interaction of the alternating electromagnetic field with the polar water molecules in the wood. Immediacy and wholeness. As long as the wood is not particularly thick, the wood can be heated through the entire thickness at the same time, and the heat penetration time is independent of the thickness of the wood.

02 What is the difference between high frequency and microwave

02-1 Different wavelengths and frequencies

Although both high frequency and microwave are electromagnetic waves, they have different wavelengths and frequencies.

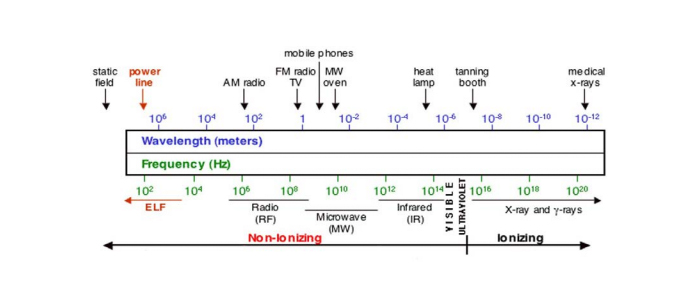

High frequency refers to electromagnetic waves with a wavelength of 7.5~1000m and a frequency between 0.3~40MHz. The working frequencies of high-frequency drying are generally 6.78MHz, 13.56MHz, and 27.12MHz. For wood applications, lower frequencies are mainly used.

Microwave refers to electromagnetic waves with a wavelength of 1~1000mm and a frequency of 300~30000MHz. The working frequency of microwave drying is usually 915MHz and 2450MHz. When heating or drying wood with high moisture content, the penetration depth of microwave in wood can reach 16cm and 6cm respectively.

02-2 Different uses

The higher the frequency, the faster the heating rate; the lower the frequency, the slower the heating rate; for the lower frequency, the heating thickness is more dominant due to the longer wavelength.

According to the properties of wavelength and frequency, high frequency and microwave with different wavelength and frequency have different application objects and usage methods.

High frequency is penetrating heating due to its low frequency and long wavelength and is more suitable for drying thick wood. Microwave is more suitable for drying thinner boards or wood due to its higher frequency and faster heating speed, but shallower heating.

03 Application scenarios of high frequency and microwave

During the high frequency and microwave drying process, the temperature of the wood surface is lower than that of the interior due to the heat loss of the wood surface and the evaporation of water. Therefore, in addition to the water content gradient, the factor that promotes the movement of water is the temperature gradient. This is also the main reason for the high frequency and microwave drying speed.

03-1 Application of high frequency

1. High-frequency vacuum dryer

Combining high-frequency drying technology with a vacuum state, it mainly uses the lower boiling point of water in a vacuum state, so as to ensure that the wood is dried at a lower temperature, especially suitable for hardwood or precious wood and other high temperature cracking phenomenon. The drying of wood, and the vacuum state is a negative pressure state, which has a certain water absorption effect, which is exactly similar to the high-frequency pressure gradient, and also accelerates the water discharge from the wood core.

Compared with traditional drying, ordinary vacuum drying, and microwave drying, high-frequency vacuum drying has outstanding advantages. There is no such thing as too high external temperature of traditional drying wood and insufficient core temperature, and no ordinary vacuum drying is still the limitation of heat conduction heating. Microwave drying is more suitable for drying thick wood, and there will be no surface cracking or even surface carbonization or burning.

2. Microwave drying equipment

Different from high-frequency drying equipment, microwave drying equipment is more suitable for uniform and rapid drying of 1-6cm thick wood boards and is often used for drying precious materials.

04 Epilogue

The application of high frequency and microwave technology in the household manufacturing industry is subdivided. The difference between the two is mainly reflected in different application objects. According to the different advantages of high frequency and microwave, the technology that is more in line with the production process is selected to make the operation faster. High efficiency, more energy-saving and environmentally friendly processes, and more high-quality and healthy products. The drying process involves almost all sectors of the national economy and is widely used in production and life, and the household industry is no exception. Compared with traditional drying technology, high frequency and microwave technology have significant advantages. With the progress of scientific research, more mechanical products using this technology will be developed, which will benefit the entire industry.