Kiln drying is one of the most important steps in turning freshly cut timber into stable, usable wood for furniture, flooring, joinery, or export. If you’ve ever wondered “What does kiln drying do to wood?”, “Why use kiln dried wood?”, or “What is kiln drying wood?”, In this article, you’ll find clear explanations to every key question about kiln drying.

In this article, we’ll cover the definition, benefits, process, types of kilns, and real-world results—plus answer the most common questions people ask about kiln dried wood.

What Is Kiln Drying?

Kiln drying is a controlled process of removing moisture from wood by placing it inside a wood drying kiln—a chamber where temperature, humidity, and airflow are carefully regulated.

Unlike air drying, which can take months or even years, kiln drying can bring wood down to the desired moisture content in just days or weeks.

Common types of wood drying kilns include:

- Conventional steam-heated kilns

- Dehumidification kilns

- Vacuum kilns – Learn more about vacuum kilns

- High frequency vacuum kilns – See our HF vacuum kiln models

What Does Kiln Drying Do to Wood?

When wood is first cut, it contains a high percentage of water—sometimes more than 50% of its weight. Kiln drying:

- Reduces moisture content to a target range (usually 6–12%)

- Stabilizes dimensions to prevent warping, twisting, or splitting

- Kills insects and fungal spores

- Improves strength and durability

- Makes finishing (painting, staining, sealing) more effective

Why Use Kiln Dried Wood?

Kiln dried wood is the preferred choice for:

- High-quality furniture manufacturing

- Hardwood flooring and paneling

- Musical instruments

- Export products requiring ISPM-15 certification

- Joinery and cabinetry where precision is critical

Quick Comparison: Kiln Dried vs Air Dried Wood

| Feature | Kiln Dried Wood | Air Dried Wood |

| Drying Time | Days–Weeks | Months–Years |

| Moisture Control | Precise (6–12%) | Variable (15–20%+) |

| Insect Control | Yes | No guarantee |

| Risk of Defects | Low | Higher |

What Is the Purpose of Kiln Drying Wood?

The primary purposes include:

- Achieving a specific moisture content for the intended use

- Meeting industry and export standards

- Improving structural stability

- Reducing shipping weight and cost

- Preventing decay during storage and transport

What Does Kiln Dried Wood Mean?

When wood is described as kiln dried, it means it has been processed in a kiln to reduce its moisture content to a specific target level.

You can identify kiln dried wood by:

- Its lighter weight compared to green wood

- A more uniform color

- A smooth feel and cleaner cuts during machining

- Measured moisture content using a meter

For small-scale projects, see our Small Wood Drying Kiln for Sale.

What Is a Wood Drying Kiln?

A wood drying kiln is a temperature-controlled enclosure designed with specialized systems such as:

- Heat source (steam, hot water, electricity, or RF energy)

- Humidity control system

- Air circulation fans

- Moisture monitoring sensors

Advanced models, such as wood drying equipment, can cut drying time in half compared to traditional methods.

Types of Kiln Drying Methods

- Conventional Kiln – Uses heated air to slowly remove moisture.

- Dehumidification Kiln – Uses a heat pump to recycle heat and control humidity.

- Vacuum Kiln – Creates a low-pressure environment, enabling moisture to leave the wood at much lower heat levels.

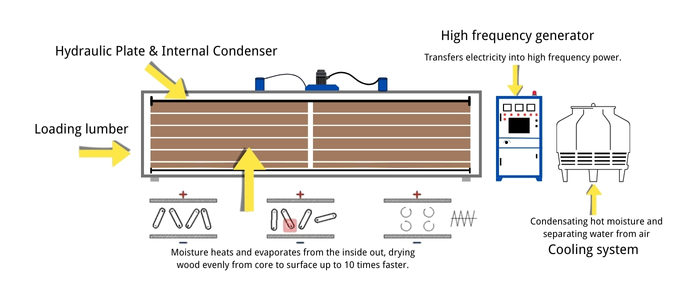

- High Frequency Vacuum Kiln – Uses radio frequency energy for ultra-fast, even drying.

FAQ – Common Questions About Kiln Dried Wood

Q: What’s kiln dried wood?

A: Wood dried in a controlled kiln environment to a specific moisture level.

Q: Why is wood kiln dried?

A: To improve stability, durability, and meet production or export standards.

Q: How long does kiln drying take?

A: Anywhere from a few days (HF vacuum kiln) to several weeks (traditional kilns).

Q: What’s the difference between kiln dry and air dry wood?

A: Compared to air drying, kiln drying works in less time, delivers consistent moisture control, and eliminates insects or fungus.

Q: Is kiln dried wood more expensive?

A: Usually yes, but it saves money by reducing waste and defects.

Case Study: Using a High Frequency Vacuum Kiln

A furniture manufacturer switched from conventional drying to an HF vacuum kiln:

- Drying time reduced from 21 days to 5 days

- Defect rate dropped by 70%

- Electricity usage reduced by 30%

Customer feedback:

“Now we’re able to take urgent orders while still ensuring the wood meets our highest quality standards. The HF vacuum kiln paid for itself in less than a year.”

Conclusion

Kiln drying wood is more than just removing moisture—it’s about ensuring stability, quality, and performance. Whether you choose a conventional kiln or an advanced high frequency vacuum model, proper drying is essential for any woodworking project.

➡ Explore our full range of wood drying kilns and see how our technology can help you achieve faster drying, better quality, and higher profits.