Wood is a hygroscopic substance that increases its moisture content because of fluctuations in humidity. Hygroscopicity is among the unique characteristics of wood. Every wood product absorbs and removes water from the air until it attains an equilibrium moisture content (EMC) which is an equilibrium point between the moisture content of the wood and the surrounding air.

Since sizes of products made from wood vary as relative humidity fluctuates so kiln drying can be considered one of the essential methods for the effective utilization of wood materials. Achieving proper machining, gluing as well as finishing is not possible as long as the amount of moisture has been diminished to a certain quantity.

Other benefits of drying are weight reduction, improved strength, and greater resistance to biological degradation from insects and fungi. So, the lumber should be dried prior to use in any further applications.

This fact sheet outlines the basic kiln drying principles of wooden materials, including the widely employed methods for drying, drying schedules, as well as some drying issues.

Kiln Drying

The kiln process is the drying of wood within the chamber where the air circulation, as well as relative humidity and temperature, are controlled to ensure that the wood’s moisture content is reduced to a minimum level without causing any drying issues.

The most frequently used Kilns are the conventional and dehumidification Kilns. Solar and vacuum kilns are employed for certain circumstances and uses.

Why Dry a Lumber or Wood?

Freshly cut lumber is lots of water. If the water isn’t eliminated, the lumber cannot be utilized to create an excellent finished product.

Dry lumber is sold at an increased price and is more straightforward to use than lumber that hasn’t been dried. When lumber is dried properly it can be machined better, is more glue-like, and is finished better.

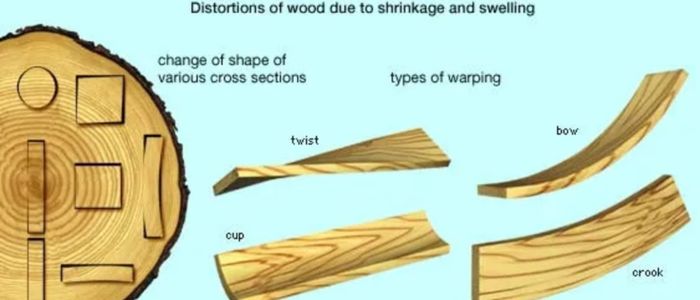

Drying increases the quality of the lumber, eliminates insects, improves pitch, retains the color, decreases weight, and reduces shrinkage. If the lumber is not dried in controlled conditions is susceptible to staining, warping, and other degrading effects that reduce the selling price and its workability.

What is Free Water, and Bound Water?

When trees are in growth, the liquid water is moving through the cells in the wood. It is referred to as free water due to the fact that it exists in the form of water and is able to be easily removed from the timber.

Bound water is the water that is part of the fiber of the wood and is much more difficult to get rid of.

After drying first, what occurs is that the free water evaporates, and then the lumber reaches what’s known as Fiber Saturation.

Fiber saturation typically occurs at the point that moisture drops close to 28 percent. When it reaches that level, the free water has gone leaving only water bound. Wood doesn’t decrease until at or below fiber saturation, and it is bound by water.

4 Methods of Kiln Drying Process

Solar Kiln

There are many kinds of solar kilns but they all rely on a type of solar collector to supply the energy needed to evaporate the water that is in the lumber. Contrary to solar heating in homes or offices for drying lumber, it isn’t possible to reduce the required heat enough to where solar heating could be comparable.

If you have a specific amount of water that needs to be removed from a specific amount of wood, it requires an amount of total heat to complete the job and that requirement isn’t able to be adjusted.

The time to dry in solar kilns is contingent on the weather which makes them in a way, unpredictable. If they’re in hot environments, they could cause damage to lumber because of excessive drying.In warmer climates, they’re inefficient and slow.

Solar kilns usually use electric fans to move air around the wood, however, the cost of running these fans is very high and due to the lengthy drying time, it is necessary to operate the fans for a long period of time which makes solar drying expensive.

The energy required to run the fans of the solar kiln is typically greater than that required when operating in a DH one because drying time is lengthier.

Conventional Kiln

A traditional kiln makes use of the heat generated by hot or steam coils, or furnaces to heat the chamber in the kiln, and then remove moisture from the wood.

The water removed from wood is transformed into the water in the form of vapor through evaporation and then drained out of the kiln by the hot air.

This process requires a large amount of heat and continuous heating of the air, which is why these systems aren’t as effective as dehumidification units.

To extract one pound of water from the lumber the kiln must draw in approximately 400 cubic feet (or 12 cubic meters) of air, then heat the air and expel it using evaporated water.

Between heating these massive amounts of air, and then heating that water until it evaporates, traditional Kilns have a large requirement for heat.

They can offer an excellent quality of lumber when they have a reliable way of controlling the temperature of the kiln in place, however, their energy consumption is greater than dehumidification kilns.

Dehumidification Kiln

Dehumidification kilns today make up the majority of frequently employed kilns used in the manufacturing of wooden products. One benefit of using dehumidification kilns is that they allow for continuous recycling of heat inside the kiln instead of discharge of heat out of the kiln as is the case with traditional kilns.

Most of the water gets condensed onto the coils of the dehumidifier before being eliminated as liquid, instead of being vented into the outside of the oven.

The air dehumidification kiln can reach temperatures of 95 to 100oF. Hot air is circulated around the wood. The warm, humid air is then cool by passing through cooling coils that are cold.

The water that evaporates turns into liquid and is then drained away into the cool water.

Vacuum Kiln

Vacuum Kilns are dated back to the 1970s, yet their use for wood drying was not developed until later.

In a traditional forced-heat dryer, the goal is to get the wood sufficiently hot to evaporate the water.

So, in a standard kiln, lumber is dried from the outside inside. If the process is forced (drying too quickly) the result is stress within the wood, which results in checks, cracks, cupping, warping, and twisting.

If you utilize the vacuum kiln for drying your wood, you’ll benefit from several advantages, such as the utilization of a lesser amount of energy for each feet, straighter, flatter lumber and less stressed lumber, and more color retention, such as in white, ash, oak, or maples, where you are aiming for the appearance of a “white” appearance.

The vacuum Dryer utilizes a vacuum to reduce the temperature when it is boiling (evaporates). Wood is more robust at lower temperatures. If we dry it at a lower temperature, we can speed up the drying process without damaging the wood. Vacuum pressure can also pull the water out of the core and into its shell. This is useful for larger sizes.

The benefits of kiln drying in woodworking

When you’re working on a task that requires carvings, turnings, or inlays, furniture pieces that are custom-designed, or any other woodwork, using a vacuum kiln to dry can accelerate the process and preserve the high quality of the wood that you pick for your project.

There are numerous advantages to using the vacuum kiln as opposed to other methods of drying wood. There are several advantages and benefits: It gives the fastest results, drying wood in 1 to 3 days. It drastically reduces the risk of dry defects, like cracks and checking. It is possible to dry wood at any level of moisture, regardless of the conditions in the environment.

When wood has used as an element of construction, be it as structural support for the construction of a structure or for the woodworking of objects it will absorb and desorb water till it’s in balance with the surrounding environment. The process of equilibration (usually drying) causes uneven shrinkage in the wood and may cause harm for the timber if it occurs too fast. The equilibration should be controlled to avoid damage to the wood.